English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

Shuairui® Automation escorts the listed electric tool company to expand steadily in Thailand

2025-04-29

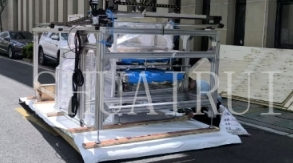

Shuairui® recently sent a batch of high-quality rotor production line equipment to Thailand. We carefully checked and inspected before shipment. We entrusted reliable international logistics to ensure that the equipment arrived in Thailand safely and on time.

1. Preparation before shipment

Equipment inspection: Comprehensively test the function and quality of the equipment to ensure flawless operation.

Equipment cleaning: Remove surface dust, oil and other impurities.

Material preparation: Prepare wooden boxes, tin foil, bubble film and other packaging materials and tools according to equipment specifications.

2. Packing and shipping

Equipment fixing: Stably place the rotor production line equipment at the bottom of the box, isolate the box wall with buffer materials, and reinforce it when necessary.

Packing: Customize wooden boxes to reasonably accommodate equipment and optimize space utilization.

Sealing: Use a nail gun to seal the wooden box to ensure stable transportation.

Label printing: Clearly mark equipment information and warning signs.

Dimension verification: Confirm that the equipment meets Thailand's import and transportation standards after packaging.

Forklift handling: Safely transfer equipment to the shipping area.

Loading: Professional team secures the equipment to prevent displacement during transportation.

Shipping: Entrust reliable international logistics to ensure that the equipment arrives in Thailand safely and on time.