English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

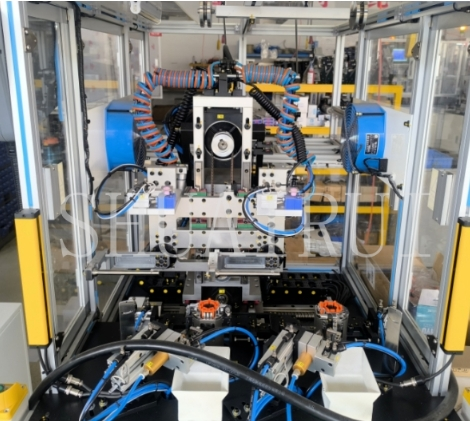

Do You Know SHUAIRUI®The Dual-Station Brushless Internal Winding Stator Winding Machine Technology?

2025-04-18

The dual-station brushless internal winding stator winding machine is an efficient and high-precision automated winding equipment designed for the internal winding process of brushless motor stators. The equipment adopts a dual-station parallel operation mode, which can simultaneously complete the winding tasks of two stators, significantly improving production efficiency. It is suitable for large-scale production in the automotive industry, home appliance industry, tool industry, industrial industry and other fields.

Core structure and function

1. Double-station winding system: The double-station brushless inner winding stator winding machine is equipped with two independent winding stations, and the servo drive system is used to achieve precise indexing and synchronous control.

2. Inner winding technology: The needle-type inner winding solution is adopted, and the winding needle is directly inserted into the stator slot for precise wiring, ensuring that the enameled wire has no crossover or overlap in a small space.

Technical advantages

1. Efficiency improvement: The dual-station design doubles the production capacity compared to the single-station equipment, and the winding cycle of a single piece can be compressed to less than 20 seconds (depending on the complexity of the stator).

2. Accuracy guarantee: The dual-station brushless internal winding stator winding machine uses an absolute encoder and linear guide rails, with a winding position accuracy of ±0.01mm and a turn-to-turn consistency error of ≤±1 turn.