English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

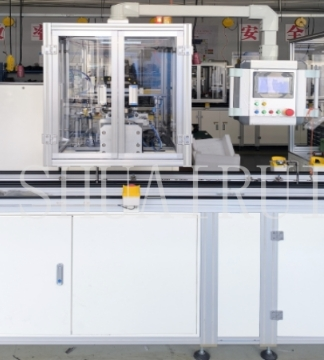

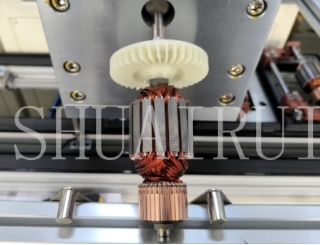

SHUAIRUI®:Rotor Blade Pressing Machine Equipment

2025-04-27

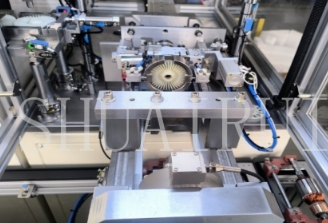

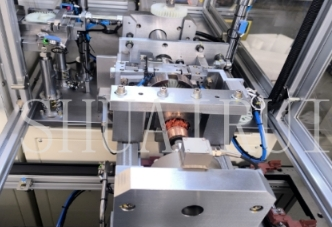

The rotor blade pressing machine is an automated equipment used for pressing rotor blades in motor manufacturing. It is based on servo motors and planetary reducers to drive electric cylinders, realizing loading and unloading and pressing. The electric cylinder output force ≥1T, stroke ≤200mm, adjustment and no-load repeated positioning accuracy ±0.01mm, pressing accuracy ±0.1mm, meeting high-precision assembly requirements.

The blade feeding system is equipped with a vibration plate with a soundproof cover, which uses the vibration principle to realize automatic sorting and transportation of materials; the working pressure range of the equipment pneumatic system is 0.4-0.6MPa to ensure the stable operation of pneumatic components.

The rotor blade pressing machine adopts a multi-dimensional error-proofing system to ensure quality: pressure sensors monitor the pressing pressure, automatically recycle defective products when exceeding the threshold, and alarm when full; photoelectric sensors monitor materials and warn of lack of materials; the full-process sensor matrix locates faults with codes to ensure that the blades are pressed without defects and achieve efficient production.